#Titanium wire

Explore tagged Tumblr posts

Text

Titanium Wire | Flexibility & Conductivity Explained

Titanium Wire is a strong, light-weight metallic wire acknowledged for its wonderful corrosion resistance and immoderate strength-to-weight ratio. It is drastically applied in aerospace, scientific implants, earrings, and commercial enterprise packages. Titanium twine gives durability, flexibility, and biocompatibility, making it best for precision engineering and specialised production desires.

0 notes

Text

Wire Mesh | Welded Wire Mesh | Titanium Wire Mesh | Hexagonal Wire Mesh

Bhansali Wire Mesh is one of the leading Wire Mesh Manufacturers in India, offering Best quality Wire Mesh solutions for various business, industrial, and construction needs. With a solid reputation for dependability and accuracy, this company assures that all goods satisfy international quality requirements.

Wire Mesh : https://bhansaliwiremesh.com/square-wire-mesh-manufacturer-supplier-exporter-india.php

Welded Wire Mesh : https://bhansaliwiremesh.com/welded-wire-mesh-manufacturer-supplier-exporter-india.php

Titanium Wire Mesh : https://bhansaliwiremesh.com/titanium-wire-mesh-manufacturer-supplier-exporter-india.php

Hexagonal Wire Mesh : https://bhansaliwiremesh.com/hexagonal-wire-mesh-manufacturer-supplier-exporter-india.php

#Wire Mesh Manufacturers in India#Wire Mesh Manufacturer#Wire Mesh#WireMesh#WeldedWireMesh#Titanium Wire Mesh#Hexagonal Wire Mesh

0 notes

Text

Inside the World of Wire Mesh: Strength, Form, and Function

Rajkrupa Metal Industries stands as a respected name in the field of industrial mesh solutions, offering high-quality Wire Mesh that meets the demands of diverse sectors. Known for our dedication to quality and innovation, we have established ourselves as a reliable Wire Mesh manufacturer in India. Our focus is on delivering mesh products that offer durability, flexibility, and long-term performance across various industrial applications.

Wire Mesh is a grid-like structure made by interweaving or welding metal wires, commonly used in construction, filtration, and manufacturing. Its high strength-to-weight ratio, resistance to heat, and ease of customization make it an essential component in both industrial and commercial environments. As a dependable Wire Mesh supplier, we provide products that can be adapted to complex designs without the need for specialized machinery, allowing seamless integration into specialized applications.

Over the years, our team of skilled professionals has helped us emerge as a trusted Wire Mesh manufacturer, providing tailored solutions for both domestic and international clients. Our mesh products are designed to withstand high temperatures and corrosive conditions, making them ideal for challenging environments. As a leading Wire Mesh supplier in India, we offer a wide range of sizes, types, and grades, ensuring that our clients receive the most suitable mesh for their projects.

.

A Closer Look at the Different Variants of Wire Mesh

Stainless Steel Wire Mesh

Inconel Wire Mesh

Monel Wire Mesh

Titanium Wire Mesh

Welded Wire Mesh

Versatility, Strength, and Thermal Stability

Wire Mesh is widely known for its strength, flexibility, and adaptability across multiple industries. Products like Stainless Steel Wire Mesh (in 304L and 316L grades) offer excellent durability and resistance to wear, making them ideal for environments that demand mechanical strength and long-term performance. These meshes are capable of withstanding high operating temperatures and are often used in construction, filtration, and architectural applications. Their lightweight yet strong structure also ensures ease of handling, transportation, and installation—making them a practical choice for both industrial and commercial use.

Corrosion Resistance and Material Performance

Each type of Wire Mesh offers specific advantages when it comes to corrosion resistance and durability in extreme environments. For instance, Inconel Wire Mesh is preferred in high-temperature and chemical-processing sectors due to its ability to resist oxidation and corrosive agents. Similarly, Monel Wire Mesh performs exceptionally well in marine and acidic environments, where traditional materials might degrade quickly. These properties make wire meshes an excellent choice for industries like oil & gas, chemical plants, marine operations, and power generation, where exposure to harsh elements is unavoidable.

Specialized Use and Application Flexibility

The unique properties of materials like Titanium Wire Mesh bring added value to industries requiring both high strength and light weight—such as aerospace, medical, and military sectors. Its corrosion resistance in chloride-rich environments and high strength-to-weight ratio makes it a reliable solution for specialized and sensitive applications. Additionally, Welded Wire Mesh offers a stable, rigid structure that is commonly used in construction, fencing, partition walls, and reinforcement tasks. These mesh types can be tailored to suit different operational needs, making them highly adaptable across diverse projects.

Ease of Fabrication and Customization

One of the key advantages of Wire Mesh is its ability to be modified into complex shapes and structures without the need for heavy or specialized machinery. Whether it’s fine mesh for precision filtration or heavy-duty mesh for structural reinforcement, wire meshes are easy to machine, bend, and weld. This allows for high customization based on project requirements. Rajkrupa Metal Industries ensures that each mesh product—whether Stainless Steel, Monel, Inconel, Titanium, or Welded—is manufactured with precision and offered in various sizes, grades, and patterns.

Long-Term Reliability and Cost Efficiency

Choosing high-quality wire mesh results in long-term performance and reduced maintenance costs. These products are designed to withstand wear, corrosion, and heat over time, minimizing the need for frequent replacements or repairs. As a result, businesses benefit from reduced downtime and improved efficiency. At Rajkrupa Metal Industries, we supply premium-grade Wire Mesh that meets both domestic and international standards, ensuring that our clients receive reliable materials that stand the test of time.

Conclusion

In conclusion, wire mesh products offer outstanding strength, versatility, and performance across various industries. From high-temperature applications to specialized filtration needs, these materials ensure long-term reliability and reduced maintenance costs. Whether for aerospace, construction, or marine use, their durability and customization options make them a cost-effective choice. Rajkrupa Metal Industries provides high-quality solutions that meet international standards, ensuring businesses benefit from dependable materials that perform consistently over time. Choosing the right wire mesh can lead to improved efficiency and lasting value For More Details:Wire Mesh Supplier in India

#Wire Mesh Manufacturer in India#Wire Mesh Manufacturer#Wire Mesh Supplier in India#Welded Wire Mesh#Titanium Wire Mesh

0 notes

Text

Latest Trends in Ferro Titanium Lumps and Cored Wire in the Steel Industry

The steel industry is continuously evolving, with new technologies and advanced materials playing a vital role in improving quality, efficiency, and cost-effectiveness. Among the key additives in steel production today are ferro titanium lumps and ferro titanium cored wire. These materials are essential for refining, deoxidation, and enhancing steel properties, especially in high-grade applications.

With increasing demands for cleaner, stronger, and more reliable steel, the use of these inputs is evolving rapidly. Let’s explore the latest trends in how these materials are being used and what steel manufacturers need to know.

1. Growing Preference for High-Purity Ferro Titanium Lumps (65% & 70%)

The market has shown a noticeable shift toward high-purity Ferro Titanium Lumps, particularly 65% and 70% titanium content grades, due to their improved metallurgical performance. These lumps are widely used for:

Deoxidation

Desulfurization

Grain refinement

Enhancing corrosion resistance in steel

The 65% grade is commonly used where a balance between performance and cost is required, while the 70% grade is preferred for premium applications where higher titanium content is essential for strengthening and microstructural enhancement.

🔍 Trend Insight:

Suppliers are focusing on offering uniform sizing, low impurities, and traceable quality to meet the exacting standards of today’s steel plants.

2. Surge in Adoption of Ferro Titanium Cored Wire Technology

One of the standout innovations in modern steelmaking is the increased use of Ferro Titanium Cored Wire. This method allows for precise, controlled delivery of titanium into molten steel during secondary refining.

Benefits Driving the Trend:

High recovery rate of titanium

Improved steel cleanliness

Lower inclusion content

Better microstructure control

Unlike bulk additions, cored wire feeding allows for real-time adjustment in composition during the ladle refining process, which enhances process flexibility and end-product reliability.

🔍 Trend Insight:

Cored wire feeding systems are becoming more automated and integrated with advanced process control software, leading to higher adoption across modern steel plants.

3. Sustainability and Waste Reduction Initiatives

Environmental concerns are pushing the steel industry toward more sustainable alloying practices. Ferro Titanium, which is often derived from recycled titanium scrap, plays a key role in this shift. Manufacturers and alloy suppliers are now emphasizing:

In particular, cored wire solutions help in:

Minimizing raw material use

Lowering energy consumption

Reducing slag and overall waste

The use of cored wire also contributes to sustainability goals by reducing the amount of alloying material required and minimizing slag generation.

🔍 Trend Insight:

The demand for green steel has made sustainability-focused alloying practices a competitive advantage. Recyclability and traceability of Ferro Titanium are now influencing procurement decisions.

4. Customization and Quality Control

Steelmakers are now demanding tailored alloying solutions, pushing suppliers to offer customized these lumps (by size, grade, or packaging) and cored wire compositions designed for specific steel grades.

Additionally, tighter quality control standards are being implemented throughout the supply chain, with a focus on:

Consistent chemical composition

Minimal contamination

Precision in delivery timing

With advancements in spectroscopy and in-line testing, real-time monitoring of alloy performance is also gaining popularity.

🔍 Trend Insight:

Suppliers who offer end-to-end quality assurance, lab-tested batches, and technical support are being favored by leading steel manufacturers.

5. Rising Demand from Specialty Steel Segments

As the market for high-performance steels—like tool steel, automotive steel, and aerospace-grade alloys—continues to expand, the demand for precision alloying using Ferro Titanium is rising. These specialty segments require consistent performance, especially in terms of:

Strength-to-weight ratio

Corrosion resistance

Heat tolerance

Both These Lumps (65%, 70%) and Cored Wire are integral in meeting the stringent specs of these high-grade steels.

🔍 Trend Insight:

The growth in EVs, defense, and infrastructure is expected to drive long-term demand for high-grade Ferro Titanium additives.

Conclusion: Staying Ahead in the Alloying Game

The evolving demands of the steel industry are redefining the roles of Ferro Titanium Lumps and Cored Wire. From automation and sustainability to precision and performance, the trends clearly point toward smarter, cleaner, and more efficient alloying processes.

For manufacturers and suppliers in this space, staying updated on these trends—and aligning offerings accordingly—is the key to staying competitive in a rapidly advancing market.

If you’re looking for a reliable supplier of above products make sure they offer quality assurance, technical support, and adaptability to your process needs.

#FerroTitaniumLumps, #FerroTitaniumCoredWire, #FerroTitanium

0 notes

Text

titanium and titanium alloys suppliers in India.

0 notes

Text

How do titanium wire manufacturers provide customized cutting, bending, surface treatment and other value-added services?

With the continuous advancement of science and technology and the diversification of industrial needs, titanium wire is increasingly used in aerospace, medical, automotive and other high-tech fields. Titanium has become an important material in many industries due to its excellent properties such as light weight, high strength, corrosion resistance and biocompatibility. In the production process of titanium wire, how to provide customized cutting, bending and surface treatment and other value-added services has become an important means for titanium wire manufacturers to enhance their competitiveness and meet customer needs.

Customized cutting service Titanium wire cutting service is one of the basic value-added services provided by titanium wire manufacturers. In many application scenarios, customers have specific requirements for the length and shape of titanium wire. In order to meet the needs of different customers, titanium wire manufacturers usually provide precise cutting services, including:

Laser cutting: High-precision cutting is achieved through laser technology, which can ensure that the cutting surface is flat and burr-free, while avoiding deformation of the titanium wire material due to high temperature.

CNC cutting: Using CNC technology, the tool is precisely cut through program control to ensure that every part of the titanium wire meets customer requirements. Manual cutting: For some customers with small batches or special needs, manual cutting can also be provided as a customized service to ensure flexibility. Through these cutting techniques, titanium wire manufacturers are able to provide a variety of lengths and sizes according to the specific needs of customers.

Customized bending services The bending of titanium wire is crucial in many applications, especially in precision engineering and medical device manufacturing. The bending of titanium wire requires not only precise angles and curvatures, but also its unique physical properties and durability. Titanium wire manufacturers generally provide the following customized bending services: CNC bending: Using CNC bending machines, titanium wire manufacturers can bend titanium wire precisely according to customer requirements. CNC bending has the advantages of high efficiency and precision, and can complete complex bending tasks in a short time, which is particularly suitable for mass production. Cold bending and hot bending: Depending on the specifications, thickness and customer requirements of the titanium wire, titanium wire manufacturers can choose cold bending or hot bending processes. Cold bending is usually suitable for thinner titanium wires, while hot bending is suitable for thicker or harder titanium wires. Customized shape design: Titanium wire bending is not limited to simple arc shapes. Manufacturers can also make complex geometric shapes according to customer needs, such as spiral, helical, or other special shapes to meet the needs of various high-end applications. These bending services make titanium wire a perfect fit in various precision applications.

Customized surface treatment service The surface treatment of titanium wire can not only improve its aesthetics, but also increase its corrosion resistance, wear resistance and other properties. Different surface treatment methods can make titanium wire better adapt to different environments and usage requirements. The customized surface treatment services provided by titanium wire manufacturers usually include: Sandblasting: Through sandblasting technology, the surface of titanium wire can form a uniform roughness. This treatment can improve the adhesion of titanium wire and is suitable for applications that require coating or painting. Anodizing: Anodizing is an electrochemical surface treatment process that can form a hard titanium oxide layer to improve the corrosion resistance of titanium wire, while giving it a unique color to meet decorative needs. Coating treatment: Titanium wire manufacturers can apply a protective coating to the surface of titanium wire according to customer needs. This coating not only increases corrosion resistance, but also improves the wear resistance and oxidation resistance of titanium wire. It is widely used in medical devices and high-end precision equipment. Polishing treatment: Polishing can make the surface of titanium wire smooth and flat, and improve its appearance quality. For some customers who have high requirements for appearance, polishing treatment is an indispensable value-added service.

Advantages of value-added services Titanium wire manufacturers can not only meet customers' diversified needs for titanium wire by providing customized value-added services such as cutting, bending, and surface treatment, but also bring them the following advantages: Improve product applicability: Through customized services, titanium wire can better adapt to the special needs of various industries. Whether it is aerospace, medical or automotive fields, it can provide specially customized titanium wire solutions. Improve product quality: Customized services ensure that every detail of the titanium wire meets strict quality requirements, effectively avoid errors in the processing process, and improve the accuracy and reliability of the final product. Save costs and time: Through precise cutting and bending services, customers do not need to process again, which can save a lot of time and cost, especially in large-scale production. Enhance customer stickiness: Providing customized value-added services can enhance customer satisfaction and loyalty, establish long-term cooperative relationships, and bring more orders and market share to manufacturers.

Titanium wire manufacturers can flexibly provide precise product solutions according to customer needs by providing customized value-added services such as cutting, bending and surface treatment. As the industry continues to deepen the application of titanium wire, manufacturers must continuously improve their technical capabilities to meet more complex and diverse market demands. Through these value-added services, titanium wire manufacturers can not only enhance their market competitiveness, but also occupy a favorable position in global competition and promote the development and innovation of related industries.

0 notes

Text

C C U ARS

CCU ARS

Cougars?

C.C. You Automatic Rifle’s

See see you ours

See see you are our’s

The top of the game playing

On a rally

Cowboy Checkered we own you

You are ours for the time we won’t all

Taking it by the small backs of Americans the blocks were thrown down long ago

The BRIC want’s all control rather than a World of All United In Continents

You small there stay there, you middle need to go down we need bigger gaps between ourselves think as in Covid in the convenient store with enlarged gaps you remain smaller

In regards to Trump Rumpty

He gave Tax breaks to further along gorge you are in the water and they on up land

You will fall to bottom if elected again!

You are in a gorge!

What’s with Musk’s Shirt?

Who paid for National Secrets?

Paid for by Governmental!

The flourishing fluorescent look compared to Trumps tan

Dark MAGA

Later on during last 30 minutes of the Rally

Dear Trump you looked eased and washed from the view at looking at you in a ball throwing dunk tank, you are not moving through space and time fast enough to be running into bugs likes this, may I throw a ball you looked washed up after the left over become, nobody washed your booth since last Assassin attempt Rally or is that white wash ethereal camouflage come on wash that to clear, it sends the wrong message’s to young one’s you are seen as pearly, the pearly glazed Trump who checked that……..Period.. … .. shit

Did he know it

Did he

Fox News recorded it

C C U

A R S

Tell us tomorrow!

I was accepted in officially back into X

After I picture post

I P P

Cute comfy underwear

Ass rear sex

That’s not me

I don’t support

Trump Vance Musk

All the names Trump gives out

That all white haired old Lady

Got damn nine years

Without magnetic

Bed or her beads and other toys

I don’t understand

CCU

ARS

Chicken Chicken-heads Red-capped

All Relative Systems

Throughout our Government

What how why!

Further segregation into states, let them battle it out!

Not a United States of America

Separation

Smaller degrees rather than whole

Wholesome Wholeheartedly O

Not for their Power

And Powers on the Earth around a Globe

This here Planet

C.C.U.A.R.S

(The pictured above chicken head, didn’t have bones it was only yolk the way it landed in boiling water and getting burned that’s what is born made for(e) purpose [pictured I])

Yea not going back too correct too

{ How ever long…… the Rally…….. }

Carrots Cabbage added Ham

That’s not an eye and beak

It tripped me out too

You know my anti’s

#wordsbymm#connecting#pourbymm#mmybsdrow#wrapbymm#ccuars#C.c.U.a.r.S#wordsbymm||mmybsdrow#letspin#galvanized wire#copper#turquoise#gold plated#titanium#platinum#all owning#and owning of shares#for(e) dividends#and any people below them#the all below TV#lost in TV#Marilyn Manson said God is in the TV#that Marilyn#rippling effect#hit west rolls through middle travesties in the East#chicken chicken-head#red-capped#marilyn manson#said it#you all are amazing

1 note

·

View note

Text

#conniescrystals#wire wrapped pendant#wire wrapped crystal#wire wrapped jewelry#handmade#labradorite#handmade earrings#handmade jewellery#crystal gems#crystals#titanium aura

0 notes

Text

Titanium Wire | Strong, Lightweight & Corrosion Resistant

Titanium Wire is a flexible and pretty treasured metal twine made from titanium, acknowledged for its extraordinary strength-to-weight ratio, corrosion resistance, and biocompatibility. It performs a vital function in masses of industries which encompass aerospace, medical, electronics, and jewellery because of its particular combination of homes that outperform many unique metals.

Properties of Titanium Wire

Titanium Wire in China is mild-weight but tremendously sturdy, with a power corresponding to some steels however at nearly half of the load. This makes it perfect for programs where reducing weight without sacrificing power is vital. The cord moreover reveals great corrosion resistance, capable of resisting harsh environments collectively with seawater, chemical materials, and high temperatures. Its resistance to oxidation permits titanium cord to preserve integrity and look through the years.

Another key characteristic is its tremendous biocompatibility, because of this that it's miles non-poisonous and not rejected through the human body. This makes titanium cord specifically appropriate for scientific packages at the facet of surgical implants, dental home gadget, and bone fixation gadgets.

Titanium cord is to be had in numerous grades and alloys, with commercially herbal titanium (Grade 1 and more than one) being common for corrosion resistance and biocompatibility, while Grade 5 titanium alloys (Ti-6Al-4V) provide advanced mechanical electricity for more worrying structural programs.

Manufacturing and Forms

Titanium cord is synthetic through a sequence of strategies along with melting, forging, extrusion, and drawing. The cord can be produced in numerous diameters, floor finishes, and coil sizes depending on the supposed use. It is likewise to be had mainly in conjunction with annealed (mild and flexible) or heat-treated (more potent and greater rigid) to meet precise requirements.

Applications of Titanium Wire

Aerospace Industry- Titanium twine is broadly utilized in aerospace due to its first-rate strength-to-weight ratio and resistance to corrosion. It is implemented within the manufacture of aircraft components, fasteners, and control cables, assisting reduce normal weight and beautify fuel performance.

Medical Field- The biocompatibility of Titanium Wire Supplier in China makes it perfect for scientific implants collectively with bone plates, screws, dental braces, and prosthetics. It helps recovery and is not going to cause allergic reactions, making it a preferred preference for long-term implantation.

Electronics- Due to its top notch conductivity and resistance to corrosion, titanium cord is also carried out in specialised digital programs collectively with connectors, resistors, and circuit additives.

Chemical Industry- Titanium wire’s corrosion resistance makes it treasured in chemical processing vegetation for applications that require resistance to acids, chlorides, and special corrosive materials.

Benefits of Using Titanium Wire

Lightweight and Strong: Offers superb strength without collectively excessive weight.

Corrosion Resistance: Ideal for harsh environments inclusive of marine and chemical settings.

Biocompatible: Safe for clinical implants and gadgets.

Durable: Long-lasting ordinary general overall performance with minimal safety.

Non-Magnetic: Suitable for specialised digital and clinical applications.

Conclusion

Titanium Wire Manufacturer in China sticks out as an excessive-common performance material that combines strength, lightness, and corrosion resistance with wonderful biocompatibility. Its several programs in aerospace, scientific, jewelry, electronics, and chemical industries show off its versatility and fee. Whether used for difficult scientific gadgets or strong aerospace additives, titanium twine remains a fabric of preference for engineers and architects aiming for reliability and durability.

0 notes

Text

TITANIUM ROUND BARS AVAILABLE IN INDIA

Ozairtradelink: Pioneers in Titanium Round Bars Manufacturing, Stockholding, and Supply in India titanium round bars suppliers in india In the dynamic landscape of industrial materials, titanium stands out as a versatile and indispensable metal, finding applications across various sectors, from aerospace to medical implants. Among the numerous players in the titanium market, Ozairtradelink…

View On WordPress

1 note

·

View note

Text

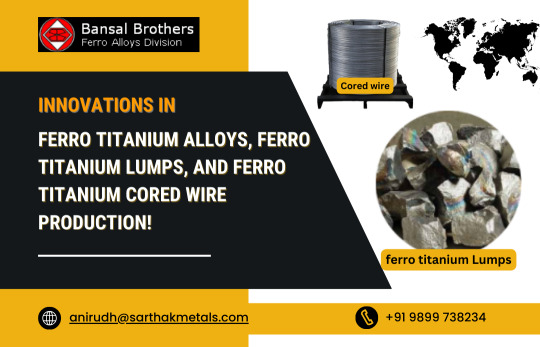

Innovations in Ferro Titanium Alloys, Ferro Titanium Lumps, and Ferro Titanium Cored Wire Production!

Ferro titanium alloys, lumps, and cored wire play crucial roles in the steel and foundry industries. These materials are primarily used as deoxidizers and grain refiners, improving steel products' strength, durability, and corrosion resistance. Recent advancements in production technologies have significantly enhanced their quality, efficiency, and sustainability. This article explores the latest innovations in the manufacturing of these essential materials.

Advanced Raw Material Processing

The quality of ferro titanium products starts with the selection and processing of raw materials. Innovations in ore beneficiation techniques, such as advanced flotation and magnetic separation, have improved the purity of titanium-bearing ores. This results in higher-grade ferro titanium alloys and lumps, reducing impurities that can affect steel quality.

Energy-Efficient Smelting Technologies

Modern smelting techniques are now focused on energy efficiency and environmental sustainability. The use of plasma arc furnaces and electric induction furnaces has reduced energy consumption while maintaining high production yields. These advanced furnaces also minimize carbon emissions, making the production of ferro-titanium alloys more eco-friendly.

Enhanced Alloying Techniques

The development of precision alloying has revolutionized the production of ferro titanium alloys. Innovations in metallurgical control allow manufacturers to achieve consistent composition and uniform particle distribution. This leads to better-performing alloys that enhance the mechanical properties of steel.

High-Purity Ferro Titanium Lumps

Manufacturers are now employing vacuum refining processes to produce ferro titanium lumps with minimal impurities. These high-purity lumps are essential in aerospace, automotive, and high-end industrial applications where material consistency is critical. The adoption of automated sorting and grading systems has also improved product uniformity and reduced material waste.

Ferro Titanium Cored Wire Advancements

Ferro titanium cored wire is widely used for precise alloying in steel production. Innovations in wire manufacturing have led to:

Improved Sheath Materials: Advanced coatings on cored wires enhance durability and prevent oxidation.

Optimized Wire Filling Techniques: Precision control in filling techniques ensures consistent titanium content, leading to more predictable results in steel refining.

Automated Feeding Systems: Modern steel plants use automated feeding mechanisms for cored wire injection, improving accuracy and reducing alloy consumption.

Sustainability and Waste Reduction

Sustainable practices are becoming a priority in ferro titanium production. Recycling titanium scrap from various industries, including aerospace and automotive, has gained momentum. This reduces the reliance on virgin ore extraction and lowers overall production costs. Additionally, waste heat recovery systems in smelting plants contribute to energy savings, making the process more efficient.

Conclusion

The production of ferro titanium alloys, ferro titanium lumps, and ferro titanium cored wire has seen significant advancements in recent years. From improved raw material processing to energy-efficient smelting and high-precision alloying, these innovations are enhancing product quality and sustainability. As the demand for high-performance steel continues to grow, ongoing research and technological developments will further refine these processes, ensuring a more efficient and environmentally friendly industry.

#ferrotitaniumcoredwire #ferrotitaniumlumps #ferrotitanium #ferrotitaniumalloys

#ferro titanium#ferro alloys suppliers#ferro titanium alloys#ferro titanium lumps#ferro titanium cored wire#ferro titanium suppliers#ferro titanium manufacturer#ferro titanium producers#ferro titanium powder#ferro titanium scrap

0 notes

Text

How to evaluate the biocompatibility and non-toxicity of medical-grade titanium wire to ensure its safety in medical implants?

As an important biomedical material, medical-grade titanium wire plays a vital role in medical implants. In order to ensure its safety in medical implants, its biocompatibility and non-toxicity must be strictly evaluated. The following is a detailed discussion of the biocompatibility and non-toxicity evaluation of medical-grade titanium wire.

Biocompatibility evaluation of medical-grade titanium wire

Biocompatibility refers to the biological response produced after the interaction between the material and the organism and the impact on the organism's tissue. For medical-grade titanium wire, the evaluation of biocompatibility is the key to ensure its safety and effectiveness. The evaluation is mainly carried out from the following aspects:

Physical property evaluation:

Mechanical properties: Medical-grade titanium wire should have mechanical properties similar to those of biological tissues, such as elastic modulus, tensile strength, hardness, etc. These properties determine whether the titanium wire can withstand the corresponding mechanical load in the body.

Surface morphology: The surface morphology, porosity, permeability, etc. of titanium wire will also affect the compatibility of the organism with the material. Smooth, non-porous surfaces help reduce friction and irritation with organisms. Chemical property evaluation: Chemical composition: The chemical composition of medical-grade titanium wire, especially the content of impurity elements, will directly affect its compatibility with organisms. For example, excessive impurity content may lead to inflammatory response or cytotoxicity. Surface activity: The surface activity of titanium wire, such as the stability and integrity of the oxide layer, is also an important factor in evaluating its biocompatibility. Biological response evaluation: Inflammatory response: One of the main physiological responses of organisms to foreign materials is inflammatory response. By observing the degree of inflammatory response of surrounding tissues after implantation of titanium wire, its biocompatibility can be evaluated. Cell adhesion and proliferation: The colonization and growth of cells on the surface of the material in the body are also important indicators for evaluating biocompatibility. Good cell adhesion and proliferation help the fusion of materials and tissues. Non-toxicity evaluation of medical-grade titanium wire Non-toxicity evaluation is a key step to ensure that medical-grade titanium wire will not release harmful substances or produce cytotoxicity when used in the body. The evaluation methods mainly include:

Cytotoxicity test: By co-culturing medical-grade titanium wire with cells, the cell proliferation, cell morphological changes and cytotoxic reactions are observed. Common cytotoxicity detection methods include CCK-8 method, etc. According to the cell proliferation rate and toxicity grade assessment standards (such as proliferation rate ≥100% is level 0, 99%≤ proliferation rate <100% is level 1, etc.), it can be judged whether the titanium wire is cytotoxic. Platelet adhesion analysis: In the coagulation cascade reaction, the platelet activation characteristics triggered by biomaterials are mainly reflected in the deformation, adhesion, aggregation and release of chemical substances of platelets. By observing the adhesion of platelets on the surface of titanium wire, its blood compatibility and potential risk of thrombosis can be evaluated. Evaluation methods and standards In order to ensure the accuracy and reliability of the evaluation, a combination of in vitro evaluation and in vivo evaluation is usually adopted. In vitro evaluation includes surface contact angle measurement, material solubility measurement, cell growth experiment, cell adhesion experiment, etc.; in vivo evaluation observes the effect of titanium wire on biological tissues through animal implantation experiments.

In addition, the production and quality control of medical-grade titanium wire should also follow strict national and industry standards. For example, the GB/T13810-2007 standard has very strict requirements and controls on the high-magnification metallographic structure and hydrogen content and other interstitial element content of two-phase titanium alloys. These standards ensure that the titanium wire has sufficient strength and plasticity, toughness and good fatigue resistance before implantation into the human body.

In summary, the biocompatibility and non-toxicity evaluation of medical-grade titanium wire is a complex and tedious process that requires comprehensive consideration of multiple factors. The safety of medical-grade titanium wire in medical implants can be ensured by combining strict in vitro and in vivo evaluation methods and following the quality control requirements of national and industry standards. This not only helps to improve the treatment effect and quality of life of patients, but also provides strong support for the research and development and application of medical materials.

0 notes

Text

It’s Wednesday!

#wrapbymm#artcalledwrap#wordsbymm#connecting#pourbymm#mmybsdrow#wordsbymm||mmybsdrow#mmybsdrow||wordsbymm#letspin#the connex#galvanized wire#copper#turquoise#and gold#platinum#white gold#diamonds#records in Money#and rooms on Titanium#to run too#international viewing#boat or private chopper#you know#thee afforded#riches#have a cabin they call it#cabinet full#and FBI sized#seized#a ramps away

0 notes

Text

#conniescrystals#wire wrapped crystal#wire wrapped pendant#wire wrapped jewelry#handmade earrings#handmade#crystal gems#labradorite#handmade jewellery#crystals#aura quartz#Titanium Aura

0 notes

Text

Titanium Wire | The Future of Lightweight & Strong Materials

Titanium Wire is a flexible fabric regarded for its electricity, low density and awesome corrosion resistance. It is usually used in industries along with aerospace, clinical, and car. Titanium twine is right for packages requiring durability, which include surgical implants, structural components, and electric connections, because of its lightweight and non-reactive nature.

0 notes